Sweat and Tears:

Toronto's Troubled Shipbuilding Industry during the Second World War

Nicholas Frado

Toronto - 2023

The city of Toronto lies in the interior of the North American continent, along the western coast of Lake Ontario. Thusly situated, Toronto was not the site of any military combat operations during the Second World War. Despite this, the city was still able to make contributions to the Allied war effort in its own way. As Canada’s second-largest city, Toronto became a manufacturer of material for the war in Europe, such as guns and munitions, making Toronto an industrial center by 1939. Overlooked by many historians, however, is Toronto’s contribution to the war on the seas. From 1940 onward, Toronto shipbuilders supplied the British and Canadian navies with five hundred twenty craft of various sizes and classes.1 This number, although impressive, conceals a deeper truth. In reality, the Toronto wartime shipbuilding industry was of dubious efficiency and effectiveness, being hampered by several obstacles including, but not limited to: the problematic geography of Toronto itself; poor industry infrastructure and lack of shipbuilding tradition; corporate mismanagement and lack of coordinated planning; as well as problems with labour procurement and organization. The story of shipbuilding in Toronto during the Second World war is fraught with challenges and problems that hindered its success.

At the beginning of the war, Toronto seemed an unlikely candidate for shipbuilding. During the First World War, when the British empire was facing a shortage of merchant ships in 1917, the Imperial Munitions Board selected several Canadian ports to manufacture various steel and wooden vessels, of which Toronto was one. After a relatively successful but very short boom in production for the duration of the war, the industry experienced a rapid and hard fall in late 1918. The government declined to distribute further contracts to Toronto shipyards and most operations were liquidated.2 The shipbuilding industry in Toronto and throughout the Great Lakes remained sparse3,4 and largely stagnant during the interwar lull.5

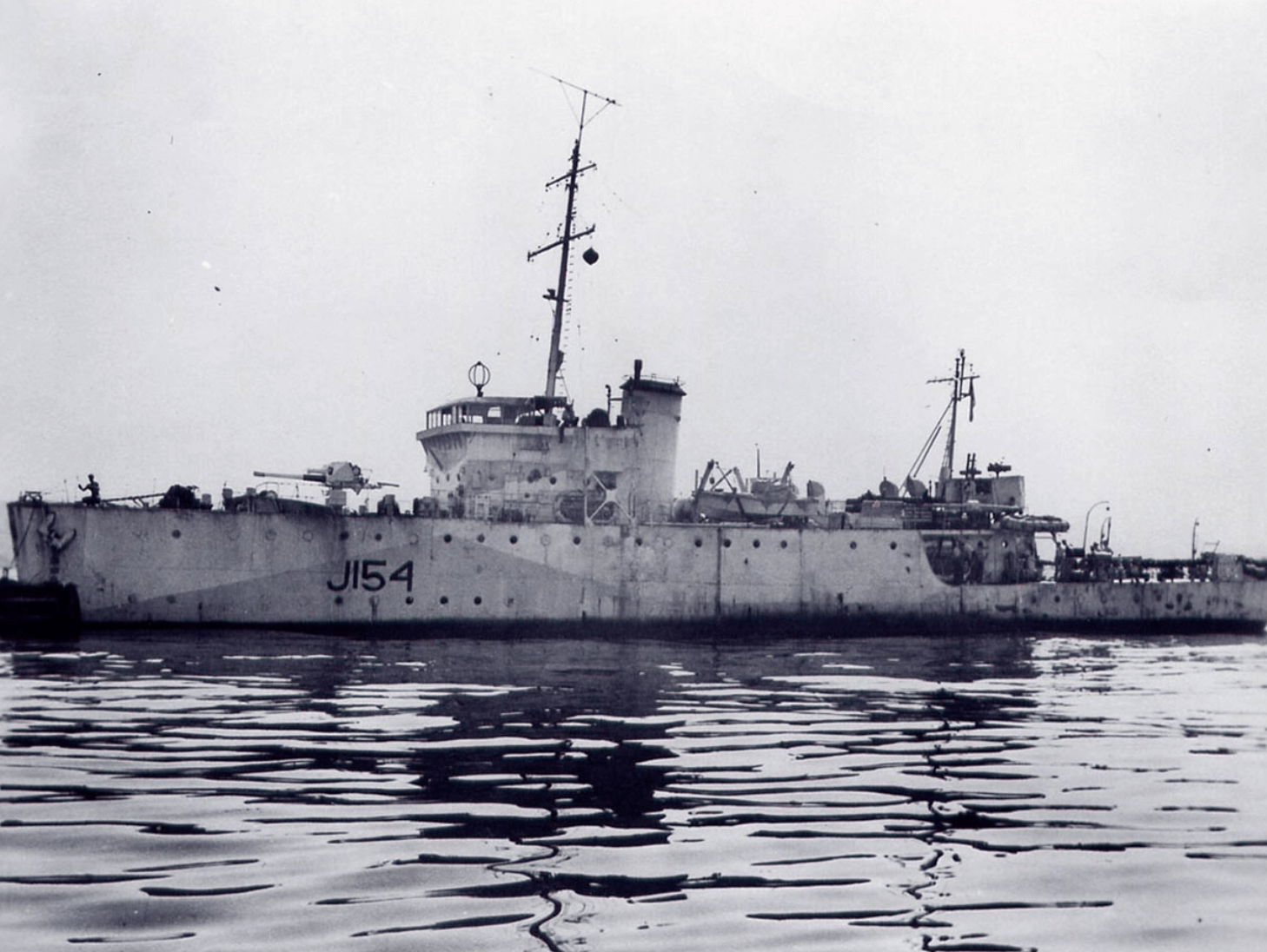

When the new war first broke out in September 1939, the Canadian admiralty initially announced a relatively conservative shipbuilding program, as it was believed at the time that the Canadian naval-industrial complex should only play an auxiliary role to that of Great Britain.6 It was only after the Fall of France in the summer of 1940 and its attendant threat to Atlantic supply chains and British naval supremacy that Canadian industrial and naval potential was fully engaged and much more ambitious plans were announced.7 The defence of Canadian coastal waters against enemy submarine and mining operations, favourite tactics of the German navy, suddenly became a concern of great importance. Thus, the building of minesweepers (see figure 1), smaller-sized wooden or steel vessels designed to detect, remove, and/or disengage naval mines became a key part of Canadian naval strategy.8 It was at this time that Toronto emerged as a shipbuilding hub for minesweepers and work “got seriously underway” at the city’s shipyards.9

Toronto was not considered an ideal location for shipbuilding, and its emergence as a shipbuilding center was largely the result of a process of elimination. It is true that Toronto did have some alluring attributes, namely the city’s large industrial and population bases.10 Toronto was home to several auxiliary industries important to shipbuilding; compass parts, switch gears, and steam engines for naval ships were all manufactured in and around the city.11 Toronto’s location, safe within the Great Lakes, also made it less vulnerable to enemy attacks than east or west coast shipbuilders.12 However, the city’s geography was a double-edged sword. Lake Ontario froze over every winter, with bothersome ice formations even reaching into Toronto harbour itself sometimes, as can be seen in figure 2.13 Although work could continue in the shipyards, vessels built in Toronto had difficulty being delivered for active duty during these months. Shipyards on the west coast were considered to have a more ideal climate for ship production, but this was undermined by their higher transportation and labour costs.14 Therefore, most production early in the war was reluctantly kept in the east.

Despite Toronto shipbuilders often not being considered by government contractors until Maritime shipyard options had been exhausted.15 In Ontario cities, such as Collingwood, Midland, and Kingston, all dwarfed by Toronto’s industrial stature, were winning arguably more important contracts.16,17 Despite there being two hundred minesweepers – Toronto’s specialty – built in Canada over the course of the war, only fifty-six were built in the country’s premier industrial city.18 Toronto simply lacked the advantage in infrastructure and know - how that more traditional shipbuilding towns had. After the sharp interwar decline in shipbuilding, there were few firms left in the city that were up to the task of building a naval fleet.19 Paradoxically, it was this lackluster shipbuilding infrastructure that was able to give the city some degree of prominence in wartime shipbuilding. Toronto’s meagre harbour was optimal for the building of smaller vessels, such as motor launch boats, scows, landing craft, and minesweepers (see figure 3).20 They would also be open to expansion later in the war when other Canadian shipyards reached capacity.21 Nevertheless, Toronto’s lack of shipbuilding infrastructure and expertise resulted in an overall unappealing port, only compensated for by the city’s vast labour pool and perceived potential for growth.

It was not long before shipbuilding efforts in the port of Toronto were frustrated by a lack of proper planning and coordination, as well as poor management. With the poor state of Toronto shipyards at the start of the war, the government found it necessary to prompt local capitalists to establish new shipbuilding companies at the port, as there were not enough currently extant to meet wartime demand.22 In March 1940, wealthy Toronto contractor James Franceschini responded to this call by establishing the Dufferin Shipbuilding Company, which was poised to become the premier wartime shipbuilder in Toronto.23 Franceschini purchased the former properties of the defunct Dominion Shipbuilding Company around the end of Spadina Avenue and established his operations there (see figure 4).24,25 In June, however, the Italian – Canadian Franceschini was interned on suspicion of holding Axis sympathies, charges which were later disproved, and his company was taken over by the government.26 The Dufferin Shipbuilding Company officially became the Toronto Shipbuilding Company in October 1941, a crown corporation under the direct control of the Department of Munitions and Supply.27 However, the move towards government administration did not necessarily provide the efficiency and security that the ministry may have been looking for under a crown corporation

The Toronto Shipbuilding Company (TSC) continued to manufacture minesweepers, but now of the newer Algerine – class, rather than the older Bangor types that had been manufactured during the first months of production.28 However, numbers suggest that Toronto shipbuilding was lagging in both speed and quality compared to other Canadian ports. In May 1941, the ministry claimed that, under its supervision, the Toronto shipyards completed hulls 70% quicker than their sluggish pace under private control in early 1940. However, this statistic looked less impressive when compared to other Canadian shipyards. Between December 1940 and June 1941, hull production time at other shipyards continued to decrease, averaging only fifty-six days in Vancouver by the end of the period. Meanwhile, Toronto shipyards’ average remained largely stagnant at around one hundred twenty days, even after the initial increase in productivity.29

Regardless of the shipyard’s efficiency, the ministry continued to put a heavy emphasis on the building of hulls at the TSC. However, this strategy was innately flawed. While the workmen busied themselves producing hulls - essentially the structure of the vessel - Toronto’s port was equipped with inadequate fitting out facilities, where all the boat’s machinery and equipment would be installed before its delivery. Completed hulls often lay idle for months in Toronto’s harbour, as the overcrowded and backlogged fitting-out centre struggled to keep up with the pace of production.30 Additionally, the subcontractors upon whom the progress of work depended often failed to deliver the needed supplies and equipment on time, which resulted in further delays and uncertainty.31 On average, fitting-out took two hundred fifty nine (259) days in Toronto, consuming more than two-thirds of the total shipbuilding time.32 When added to hull construction time, this meant that it often took over a year for any one minesweeper to be completed, a sluggardly pace for such a relatively small vessel. The situation in Toronto eventually became so poor that the TSC was compelled to open specialized fitting out yards at other ports in the country in order to finish ships within a reasonable timeframe.33,34 Thus, the TSC’s “great lack of co-ordination” in construction, as well as “lack of plans and slow delivery of materials” have been cited by historians as key causes for the general inefficiency that prevailed at the shipyard.35

The management of the Toronto Shipbuilding Company also proved volatile and unimpressive. Harold Milne, an advisor to the shipbuilding branch of the Ministry of Munitions, observed that management exerted little central control over operations, delegating a great deal of authority to head foremen. Toronto, however, was lacking in men with expertise to carry out foreman duties, and so the few number of men in the position found themselves “scattered in the yard and overloaded with work.”36 Throughout the company’s existence, it relied heavily on the advice and expertise of the British Admiralty Technical Mission, specially set up to offer assistance to inexperienced Canadian shipbuilders.37 This assistance, however, was limited at times and often unclear.38 In fact, upon their delivery to the Royal Navy, embarrassing defects were discovered in many Toronto-built ships, despite the fact they were based on British instructions.39 The chaotic state of production did not go unobserved by visitors to the shipyard. In a piece reporting the launch of the HMCS Nipigon in September 1941, the Toronto Daily Star admitted that work at the shipyards appeared as “hopeless confusion.”40 Although the author was quick to assure the public that work was going smoothly underneath the chaotic veneer, there was more truth to this observation than he let on.

Company executives did not prove much more effective than their subordinates. Company leadership had been reshuffled three times since its founding in March 1940, hardly providing stable leadership. It did not help that many of the highly placed appointees had no experience in shipbuilding and were chosen more for their supposed business expertise.41 The ministry was not blind to the company’s disappointing results. Ultimately dissatisfied with its performance as a crown corporation, management of the TSC was handed over by the government to private interests in the summer of 1943, and the Redfern Construction Company oversaw operations at the shipyards until the end of the war.42,43 Its time under ministry administration was not remembered fondly. Overall, poor planning and general mismanagement had caused and compounded delays that rendered shipbuilding in Toronto significantly less efficient than it ought to have been.

Toronto shipbuilding also had difficulties with its relationship with the industry’s labourers. From the beginning of operations, the procurement of labour was problematic. At the beginning of the war, it was difficult to get sufficient labour for Canadian shipyards and “a large proportion” was untrained.44 Although Toronto had a large population, Toronto was not an exception to the labour problems. In fact, the 4,000 workers employed at Toronto shipyards represented only a “small but unknown percentage of direct wartime manufacturing in the city,” and it is likely that the demand for Toronto’s other vast wartime industries sucked labour supply away from the docks.45 For many of the TSC’s young workers, this was their first full-time job, indicating the lack of experienced workers at the shipyard.46 Several hundred women were also employed by the company. While most worked in clerical positions, some served in rather unorthodox, male-dominated roles labouring on the docks (see figure 5), further suggesting the company was wanting for such workers.47 By 1943, Canada was facing an overall labour shortage, putting further stress on the already stretched thin labour force of the Toronto shipyards.48

In January 1942, the Toronto Daily Star boasted that in Canada “less time has been lost [from labour troubles] than in any other shipbuilding nations, figures show.”49 While this may have been true as a general rule, Toronto shipbuilding was certainly not immune from worker discontentment. Indeed, workers had cause for some legitimate grievances. From 1939 to 1942, wages declined from 44.1% of the gross selling value of Canadian shipyards’ products to 29.6%, although this number later rebounded by the end of the war.50 The first major labour row at the Toronto shipyards occurred in May 1941, when a government conciliation board was established to arbitrate wage disputes between the Dufferin Shipbuilding Company and various unions representing different types of workers in its yards.51 No job action occurred, however. This example is illustrative of how most labour disputes at the Toronto shipyards were resolved. Only once, in June 1943, did any type of job action organized by unions occur, when a brief work stoppage led to the termination of less than 300 men.52 Otherwise, disputes generally went directly to government conciliation without any work stoppages. However, the lack of a substantial Great Lakes shipbuilding industry before the war meant that the government sometimes struggled to find a reasonable standard against which to judge the workers’ demands.53 This often resulted in inconsistent decisions being made by the conciliation boards.

Despite the lack of union-organized job action, worker-management clashes sometimes took place outside of formal, legal channels. After a superintendent from the TSC fitting out department was fired for “inefficiency” in May 1942, 200 men walked off the job.54 The workers claimed that his termination was motivated by jealousy, and that his accusers were, in fact, the inept ones. The walk-out was not organized by a union, and the workers came back after two hours, facing few real consequences. Additionally, some workers resented the imposition of “efficiency men” brought in by the ministry to increase productivity, and the evidently unpopular measures they inflicted.55 In August 1943, his difficult clashes with unions were rumoured to have played a role in TSC president Gordon Leitch’s premature retirement.56 Whatever the avenue of conflict or the result, labour disputes undermined the management and productivity of Toronto shipyards, and problems in procuring sufficient manpower remained a thorn in the company’s side for the duration of the war.

The Toronto Shipbuilding Company did not last much longer than the Second World War. Work began winding down already in 1944, and the company’s last minesweeper was delivered on August 28, 1945. The company, having served its purpose for the government, was dissolved in 1946, spelling the end of major shipbuilding operations in Toronto.57 Throughout its brief existence, the Toronto wartime shipbuilding industry was beset by several challenges - some inherent, others preventable, - and delivered underwhelming results for a city of its stature. Its location on Lake Ontario caused delays in delivery, especially during the frozen winter months, and the port lacked key shipbuilding infrastructure and expertise. The shipyards’ poor management under government control led to bad co-ordination and slow industry progress. A lack of skilled labour and bickering unions only compounded the problems already faced by the industry. Therefore, it is no surprise that several historians have issued damning verdicts on the TSC. None of this, however, is meant to devalue Toronto’s contributions to the war on the seas. For all its flaws, the company did provide the Allies with crucial minesweeping vessels and hundreds of smaller craft during the height of the war. The hard work of the shipyard workers, as well as the good intentions of executives and government officials should not be overlooked or minimized. It is simply regrettable that an industry of such great potential was plagued by setbacks and inefficiency, facts which historians must recognize.

-

James Pritchard, “Fifty-Six Minesweepers and the Toronto Shipbuilding Company during the Second World War,” The Northern Mariner 16, no. 4 (October 2006): 29. ↩

-

Michael Moir, “Toronto’s Waterfront at War, 1914 – 1918,” Archivaria 28, (Summer 1989): 133. ↩

-

The premier Toronto shipbuilder during the First World War, the Dominion Shipbuilding Company, went bankrupt in 1920, but its facilities were later reused in 1941. The only Toronto shipbuilder from the war that survived past the 1920s was the Toronto Shipbuilding Company, alternatively known as the Toronto Dry Docks.3 This company should not be confused with the later crown corporation also named the Toronto Shipbuilding Company, which operated from 1941-1946. Post-war, the Toronto Dry Docks’ operations were reduced only to ship repairs and the construction of scows and tugs; it did not play a major role in shipbuilding efforts during the Second World War. ↩

-

Moir, “Toronto’s Waterfront,” 134. ↩

-

James Pritchard, A Bridge of Ships: Canadian Shipbuilding during the Second World War (Montreal: McGill-Queen’s University Press, 2011), 41. ↩

-

Gilbert Norman Tucker, The Naval Service of Canada: Its Official History, volume II (Ottawa: King’s Printer, 1952), 5. ↩

-

Michael Hennessy, “The Rise and Fall of Canadian Maritime Policy, 1939 – 1965: A Study of Industry Navalism and the State” (PhD Diss., University of New Brunswick, 1995), 48. ↩

-

Figure 1: “HMCS NipigonI,” Government of Canada. https://www.canada.ca/en/navy/services/history/ships-histories/nipigon.html; Tucker, Naval Service, 21. ↩

-

Pritchard, “Fifty-Six Minesweepers,” 30. ↩

-

Moir, “Toronto’s Waterfront,” 127. ↩

-

J. de N. Kennedy, History of the Department of Munitions and Supply, (Ottawa: King’s Printer, 1950), 232 – 233; Pritchard, A Bridge of Ships, 236. ↩

-

Moir, “Toronto’s Waterfront,” 127. ↩

-

Figure 2: Dangerous Beauty – Ice formations rivaling the Artic seas can be found along the waterfront. Lifesavers warn that the towering cliffs may collapse in the sun, photograph, Toronto Public Library Digital Archives, February 3, 1939, https://digitalarchive.tpl.ca/objects/236799/dangerous-beautyice-formations-rivalling-the-arctic-seas-ca?ctx=d2fc2fa10d527bac41e15448f4763f8cea196c48&idx=31. ↩

-

Tucker, Naval Service, 40. ↩

-

Pritchard, “Fifty-Six Minesweepers,” 30. ↩

-

In addition to building minesweepers of their own, the other Great Lakes shipyards produced fifty corvettes in total, serving as the Royal Canadian Navy’s “primary antisubmarine vessel and ocean escort.”15 Further down the St. Lawrence system, larger frigates and cargo ships were constructed in Quebec, with Montreal even boasting “Canada’s premier shipyard.”15 It reflected poorly on Toronto that it was relegated to the construction of the humble minesweeper. ↩

-

Pritchard, “Fifty-Six Minesweepers,” 50-51, 80, 75. ↩

-

Pritchard, A Bridge of Ships, 9; Pritchard, “Fifty-Six Minesweepers,” 29. ↩

-

Tucker, Naval Service, 41. ↩

-

Figure 3:Toronto Island Airport, Hanlan’s Point, photograph, Toronto Public Library Archive, 1940, https://digitalarchive.tpl.ca/objects/353885/toronto-island-airport-hanlans-point?ctx=07b7c144a4b6a584f7dfb24c80b8a188714d4a9c&idx=144. ↩

-

Pritchard, “Fifty-Six Minesweepers,” 34. ↩

-

Pritchard, “Fifty-Six Minesweepers,” 30. ↩

-

Pritchard, “Fifty-Six Minesweepers,” 31. ↩

-

There is contradictory information regarding the exact location of the Dominion/Dufferin/Toronto Shipbuilding Company. Sources generally agree that it was in the area at the end of Spadina Ave., but it is also possible it may have been closer to the end of Bathurst St (the “bridge” above Loblaw Groceterias on the map). In theory, the shipyard might have been located anywhere between Dufferin Paving (the location of Franceschini’s main construction company) and the wharf that included Dominion government land. ↩

-

Figure 4: Toronto Harbour Commissioners: Progress Plan, map, York University Digital Library, 1932, https://digital.library.yorku.ca/yul-1151505/toronto-harbour-commissioners-progress-plan. ↩

-

Pritchard, “Fifty-Six Minesweepers,” 31. ↩

-

Pritchard, “Fifty-Six Minesweepers,” 35; Kennedy, History of the Department, 454. ↩

-

Kennedy, History of the Department, 454. ↩

-

Pritchard, “Fifty-Six Minesweepers,” 37. ↩

-

Pritchard, “Fifty-Six Minesweepers,” 39. ↩

-

Pritchard, “Fifty-Six Minesweepers,” 38, 44. ↩

-

Tucker, Naval Service, 55. ↩

-

A fitting out yard was established in St. John, New Brunswick, partly to avoid the Great Lakes freeze-up during the winter months which had caused even further delays in delivery. Later, another was established at Hamilton, and vessels began to be redirected to Kingston specifically for the installation of asdic, a radar technology crucial for minesweepers.31 ↩

-

Kennedy, History of the Department, 454; Pritchard, “Fifty-Six Minesweepers,” 45. ↩

-

Pritchard, “Fifty-Six Minesweepers,” 37-38. ↩

-

Pritchard, “Fifty-Six Minesweepers,” 37-38. ↩

-

Tucker, Naval Service, 55. ↩

-

Pritchard, “Fifty-Six Minesweepers,” 38. ↩

-

Pritchard, “Fifty-Six Minesweepers,” 39. ↩

-

“First Toronto Naval Unit Minesweeper Launched,” Toronto Daily Star, September 30, 1940, 2. ↩

-

Pritchard, “Fifty-Six Minesweepers,” 35-36. ↩

-

44Pritchard, “Fifty-Six Minesweepers,” 47. ↩

-

Though the government technically retained ownership of the company and its facilities, the Redfern Construction Company took over management operations and produced ships under the “Redfern Shipbuilding Company” marque. It was under Redfern administration that asdic installation was moved partially to Kingston, and the speed of deliveries was improved.38 However, this can also be attributed to a general slowdown of shipbuilding on the lakes mid-war, which meant less hulls were competing for the same space and time. Despite these improvements, they came at a time when the navy’s shipbuilding programme was already coming to an end. They might have had more effect had they been implemented earlier in the war. ↩

-

Tucker, Naval Service, 41. ↩

-

Pritchard, A Bridge of Ships, 217. ↩

-

Pritchard, “Fifty-Six Minesweepers,” 45. ↩

-

Figure 5: Welder and assistants working on hill of Royal Navy Algerine Minesweeper – Toronto shipbuilding company, photograph, Library and Archives Canada, (undated), ; Pritchard, “Fifty-Six Minesweepers,” 45. ↩

-

Pritchard, A Bridge of Ships, 43. ↩

-

“Canada-Built Ships Play Big Part in U-Boat Pursuit,” Toronto Daily Star, January 10, 1942, 4. ↩

-

Pritchard, A Bridge of Ships, 315-316. ↩

-

Department of Labour, Canada. The Labour Gazette 41 (Ottawa: King’s Printer, 1941): 620. ↩

-

Pritchard, “Fifty-Six Minesweepers,” 44-45. ↩

-

Pritchard, “Fifty-Six Minesweepers,” 41. ↩

-

Pritchard, “Fifty-Six Minesweepers,” 41-42. ↩

-

Pritchard, “Fifty-Six Minesweepers,” 41-42. ↩

-

Pritchard, “Fifty-Six Minesweepers,” 46. ↩

-

Pritchard, “Fifty-Six Minesweepers,” 47-48. ↩